Current Research

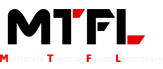

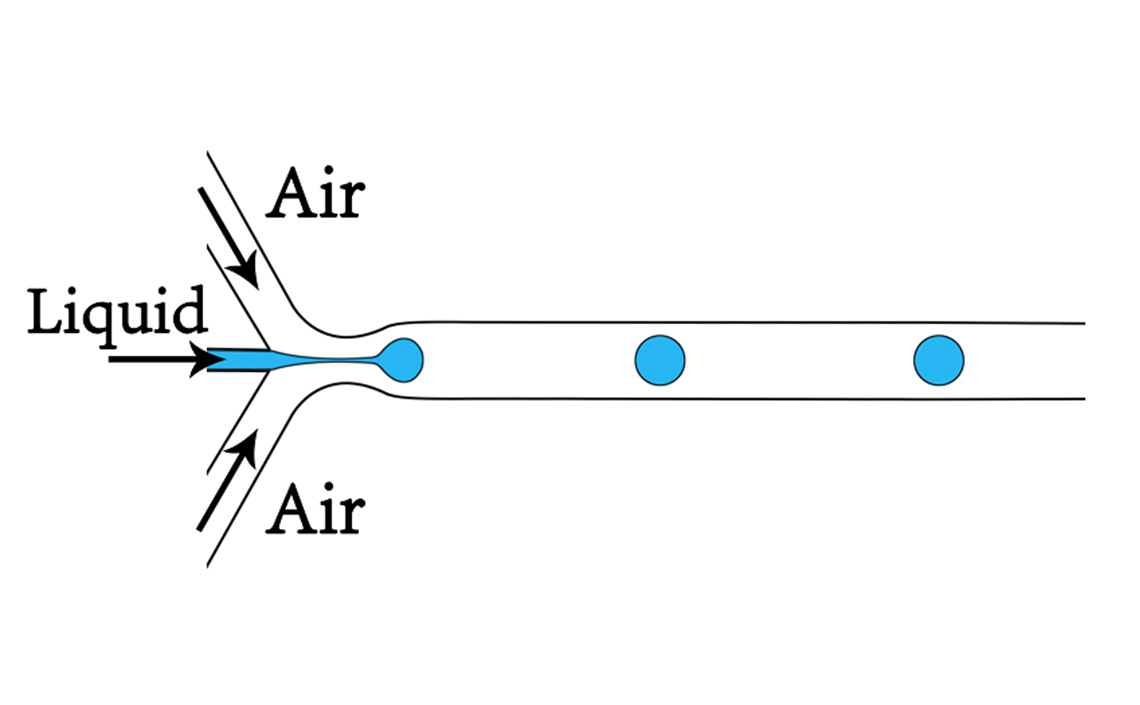

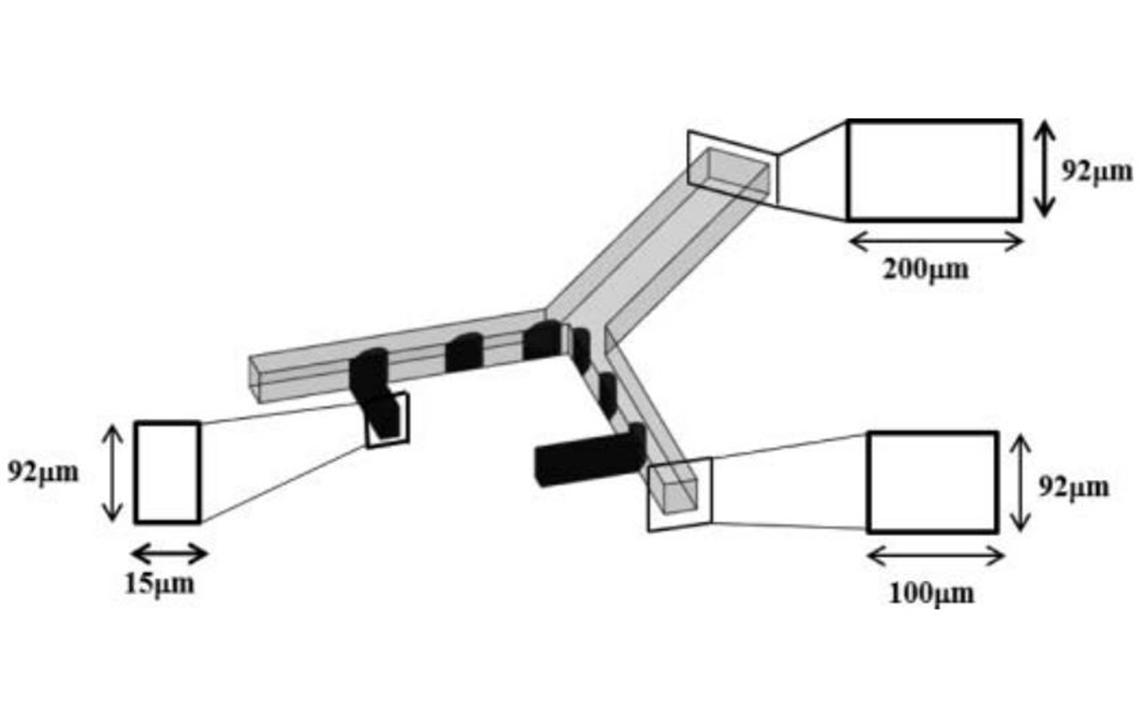

Liquid-Gas Droplet Microfluidics

The historical trends of droplet-based microfluidics employ continuous phases that are more viscous than the discrete phase, such as oil-water. In an effort to increase droplet throughput and mixing rates, MTFL is actively developing and testing the next generation of gas-liquid microfluidic devices. Research efforts are focused on the two most critical tasks: droplet generation and mixing.

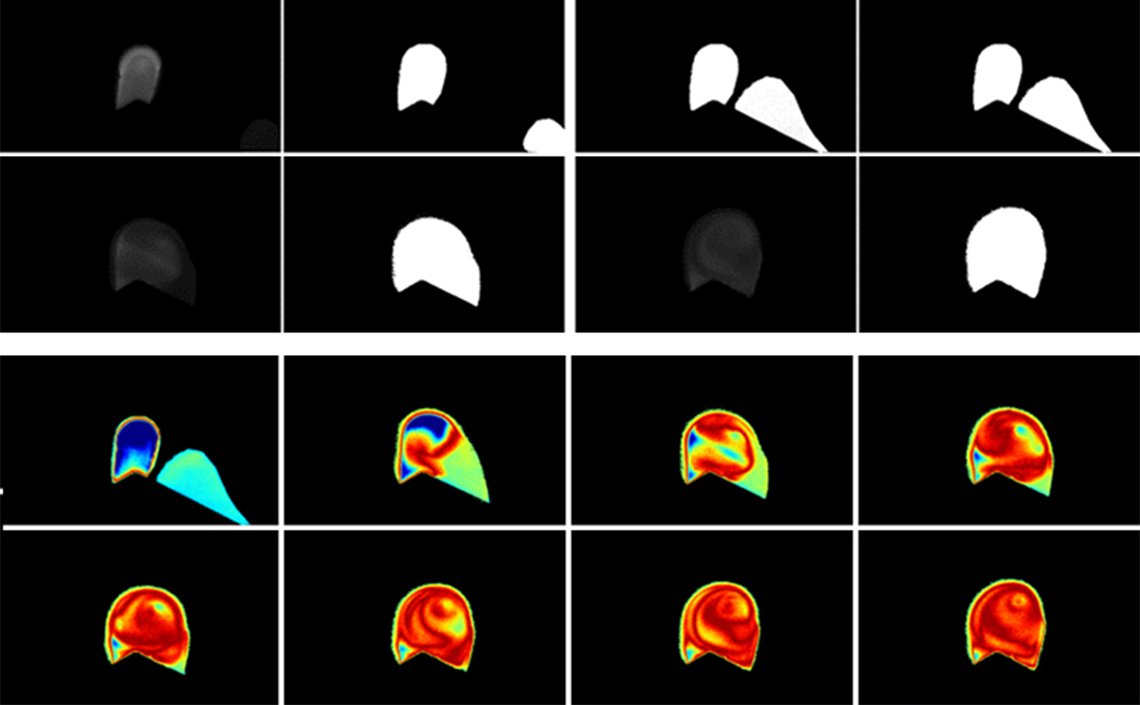

Read MoreOptical Diagnostics

MTFL has developed and integrated a novel droplet dynamics measurement technique that employs a single fluorophore laser-induced fluorescence, custom image processing, and statistical analysis for determining droplet volume, translation velocity, and frequency as well as monitoring and quantifying mixing in confined, high speed droplet collisions.

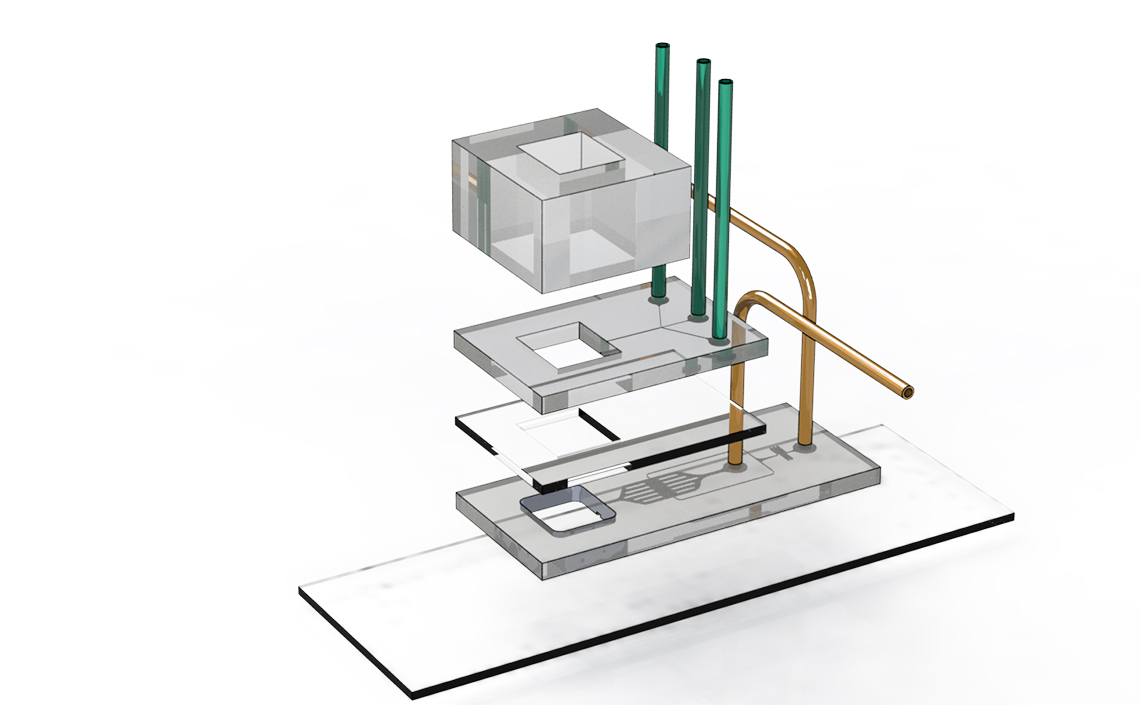

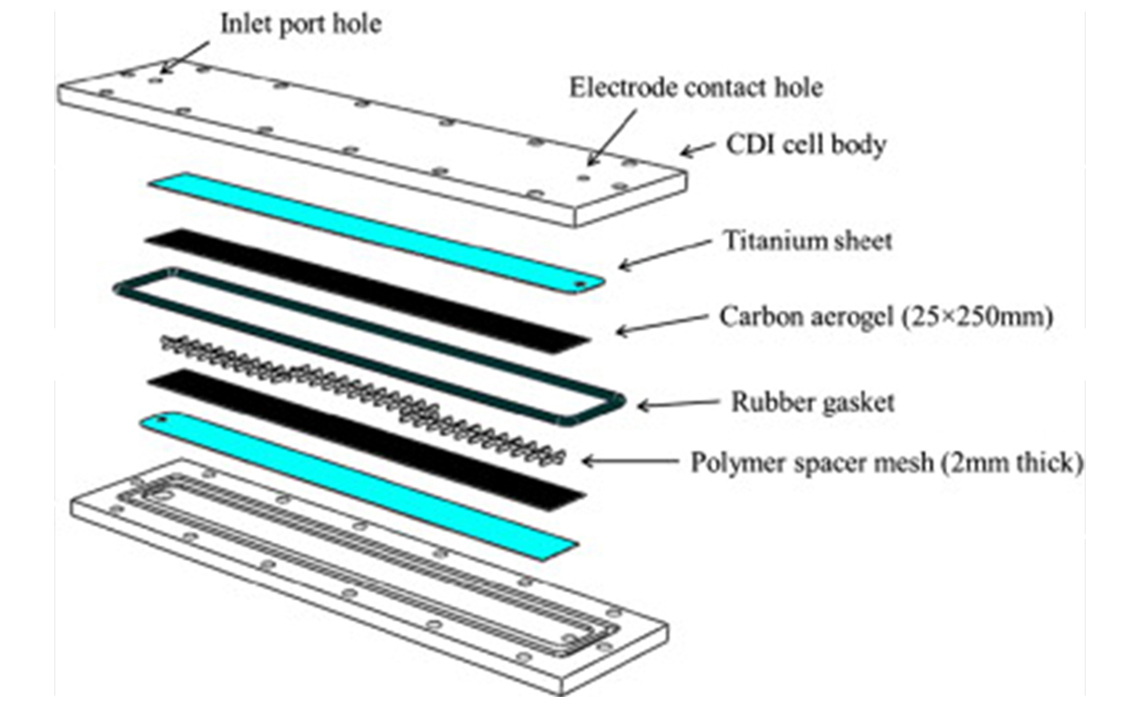

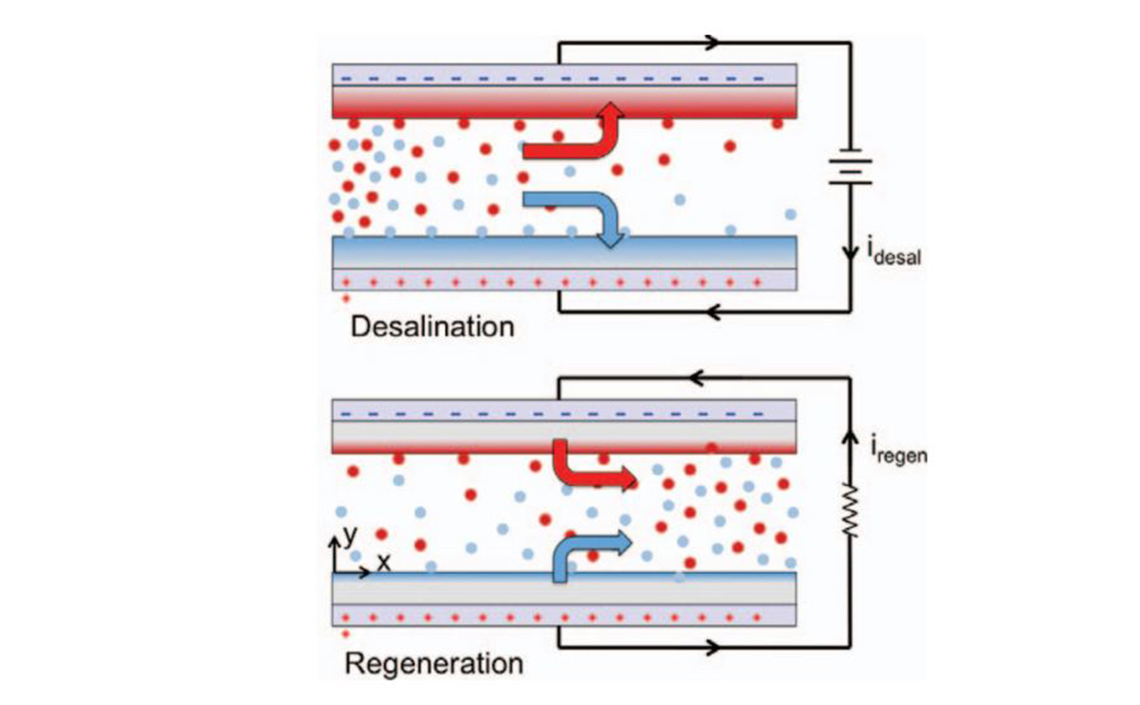

Read MoreCapacitive Deionization (CDI)

Our research objective is to understand the ionic transport and adsorption kinetics that occur in a CDI system to improve its overall performance and investigate other potential applications of electro-adsorption processes such as waste water treatment and spent nuclear fuel reprocessing.

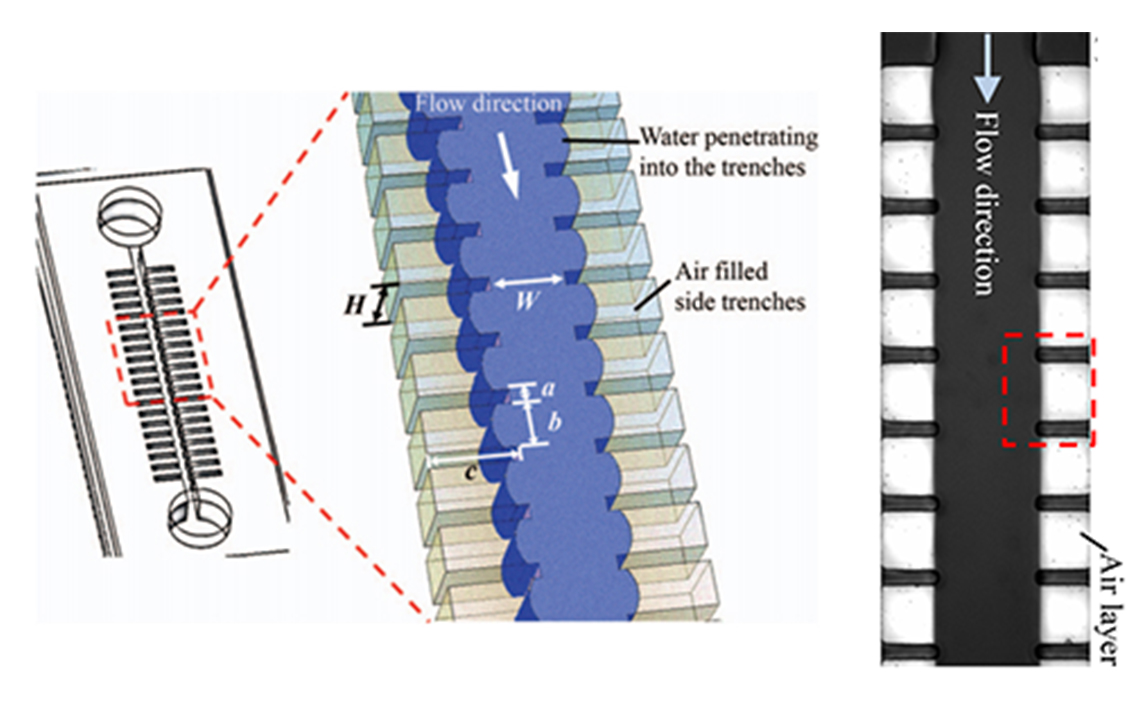

Read MoreFriction Reduction

Drag/friction reduction has been a key interest in reducing energy consumption for various applications. One method to reduce drag/friction is to render the surface of interest superhydrophobic. Our research goal on superhydrophobic surfaces is to understand how the friction reduction is affected by different pressures or thermal conditions.

Read MorePast Research

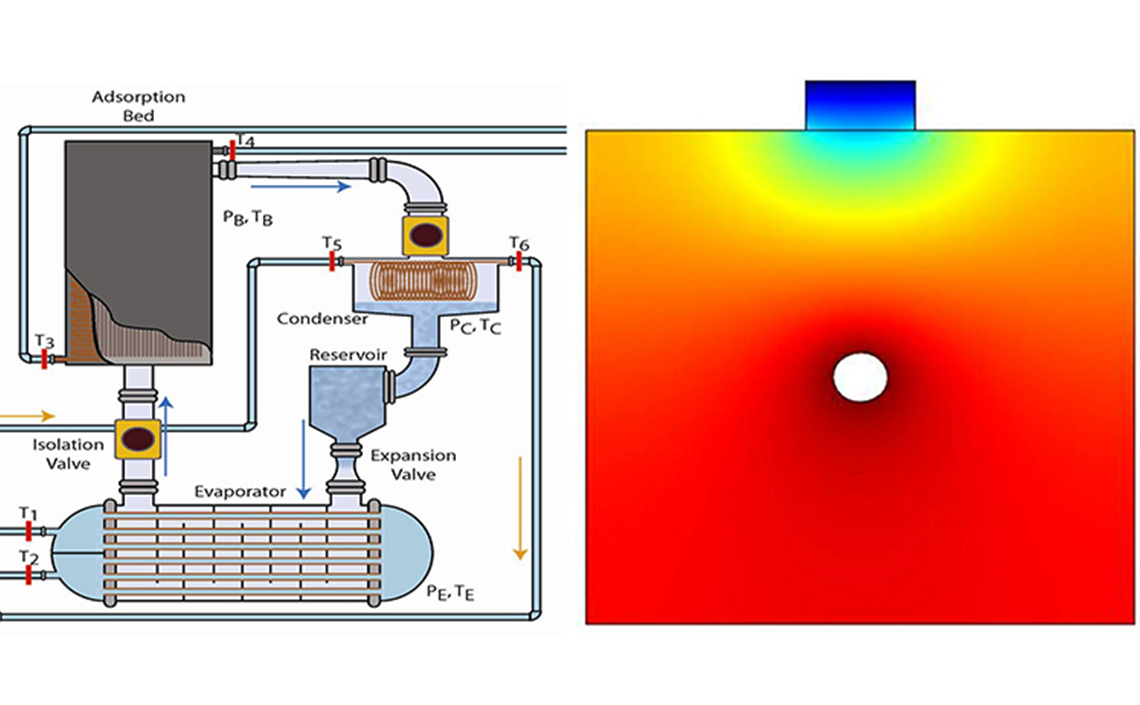

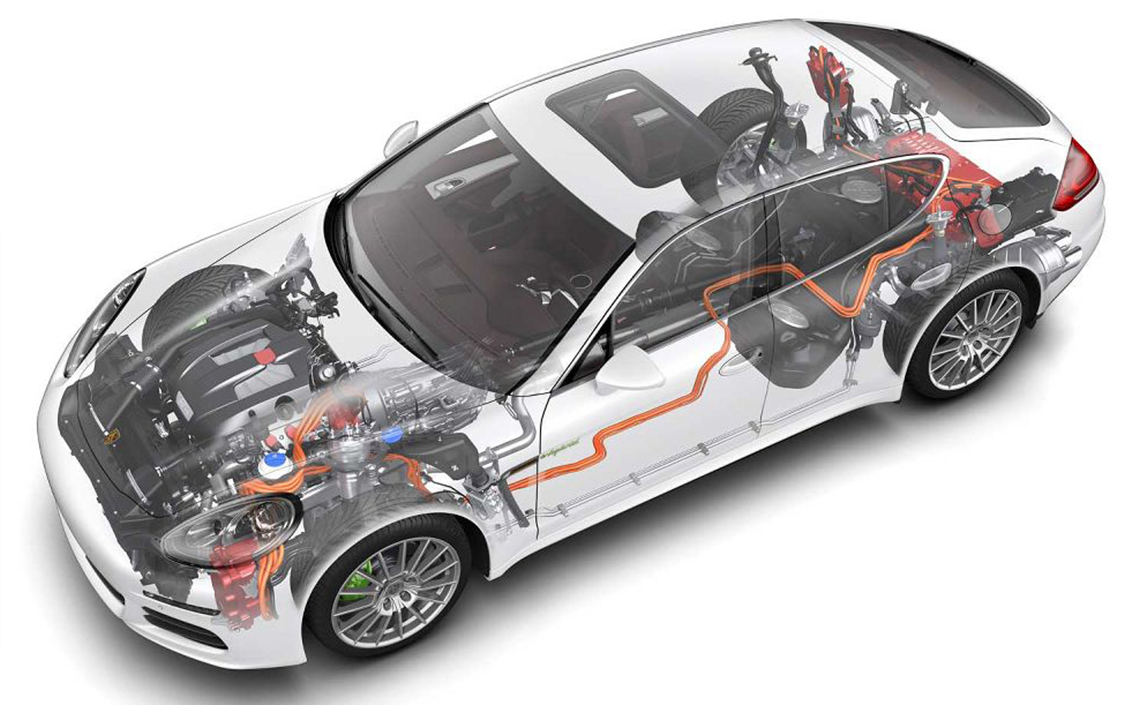

Advanced Thermo-Adsorptive Battery (ATB)

Working alongside collaborators at MIT, UC-Berkeley, and Ford Motor Company, MTFL researchers are designing and testing a compact, lightweight, and high-capacity novel adsorption cycle for electric vehicle (EV) cabin climate control with minimal battery drain.

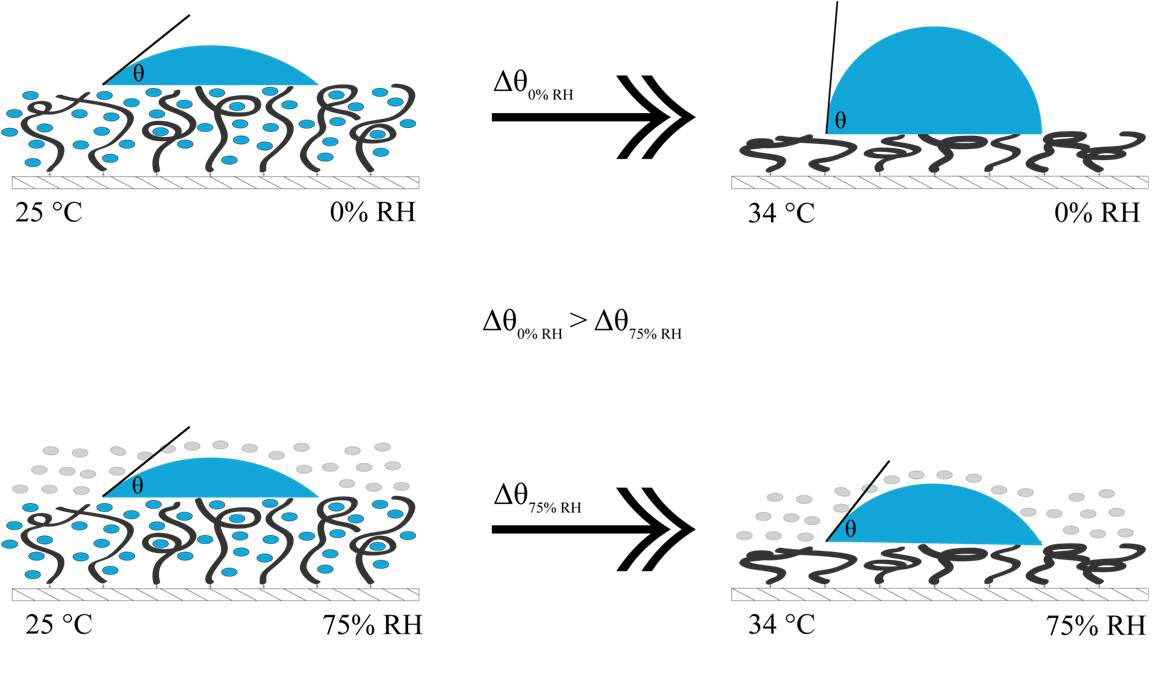

Read MoreNanopolymeric Surface Characterization

Thermoresponsive polymers can be used to change the wetting characteristics of a system treated with them under different heat loads. Researchers at MTFL are performing wetting characterization of Poly(N-isopropylacrylamide) (PNIPAM) treated surfaces under different conditions for use in self adjusting microelectronics cooling systems.

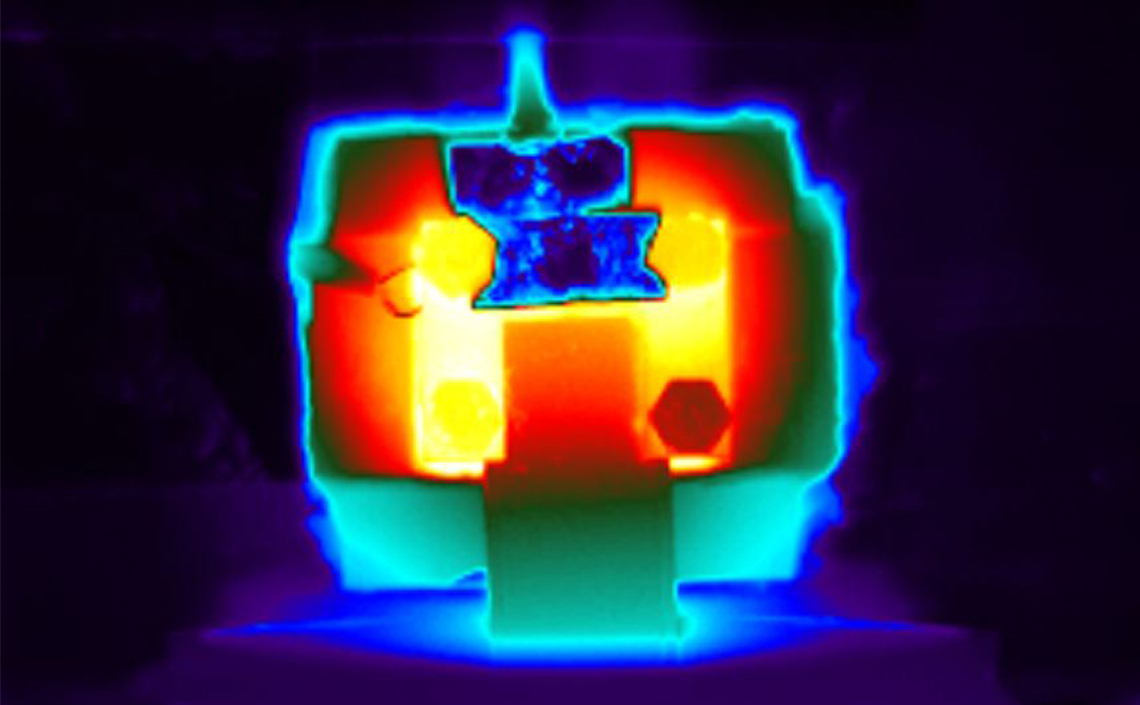

Read MoreThermal Wick

The thermal wick project aims to first understand the effect of micro-scale material geometries on capillary fluid flow and phase changes, then to develop microstructured wicking materials capable of dissipating at least 1 kW/cm2 for heat pipe applications.

Read MoreEducational Lab Modules

MTFL researchers have developed an educational module for use in the undergraduate Fluid Mechanics lab, ME130L. This module educate students about the fundamentals of the conservation of mass through the use of epi-fluorescence microscopy, optical diagnostics through image processing, and PDMS T-junction microchannels.

Read More