New Research on Liquid Metals Leads to Innovative Developments

ChE Associate Professor Steve Lustig’s new research on liquid metals creates an exciting and innovative pathway for developments in the technology and aerospace industries.

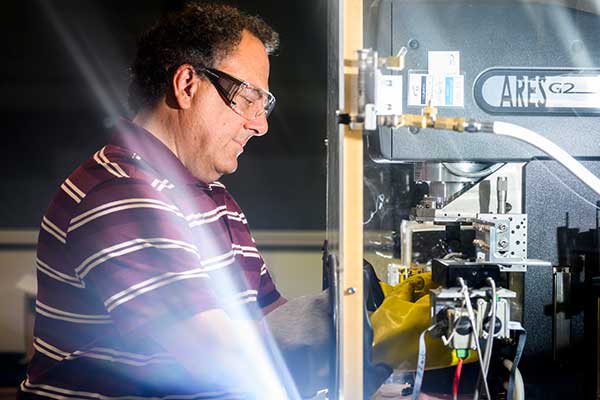

This article originally appeared on Northeastern Global News. It was published by Cody Mello-Klein. Main photo: The work done by Lustig and his collaborators provides the foundation for future work on organic metals. Photo by Matthew Modoono/Northeastern University.

Researchers achieve new insights about liquid metals, opening doors for the creation of new materials

When most people think of liquid metal, they think of the T-1000 from “Terminator 2.” Steve Lustig sees a chemistry kit.

Recent research from Lustig, an associate professor of chemical engineering at Northeastern University, provides new insights into how organic chemistry can be done in high temperature liquid metals to change their chemical makeup. The foundational work done by Lustig and the researchers involved in this paper, published in Science Direct, opens up pathways to create entirely new kinds of organic metals with direct impacts on everything from electronics to engineering.

“This opens up the possibility of designing and achieving completely new types of materials,” Lustig says. “There really are no materials that are quite like this where you have a metal and organic structures inside the metal that seem to be bonded together in ways that have not been documented in the literature before.”

The challenge with liquid metals has long been even being able to understand that chemistry can occur inside of them. As a solvent to which chemists can add a solute to create a chemical solution, liquid metals are tough to work with for understandable reasons: They’re opaque and generally impermeable.

It creates a problem for chemists and chemical engineers. Suddenly, the tools and methods they normally use to probe into the results of their work are ineffective. Lustig says the only ways for chemists to validate and diagnose their work on liquid metals was to mechanically test bulk samples, which provides very limited information, or investigate slices of the material. The latter ends up damaging the material, with most damage done on the surface, the only place chemists are able to investigate the results of their experiments.

To avoid these pitfalls, the researchers found a novel use for a tried-and-true method: inelastic neutron scattering. As the name implies, inelastic neutron scattering involves dispersing neutrons through a material, using the atomic vibrations of the material to understand more about its makeup.

Read full story at Northeastern Global News