New Robotics Lab to Lead to Innovative Research

The newly opened space in EXP for the Institute of Experiential Robotics will allow for interdisciplinary collaboration in the advancement of robotics.

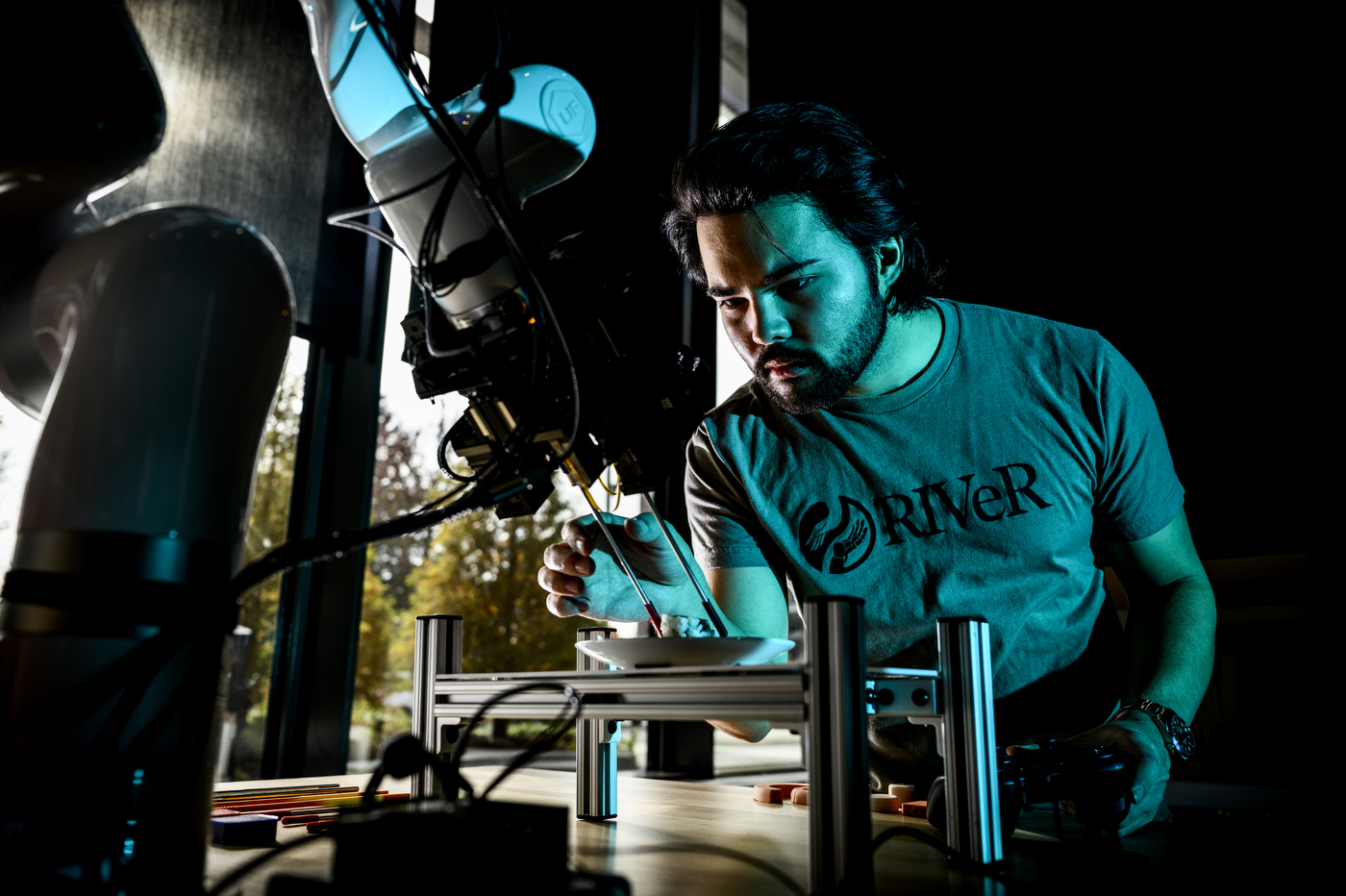

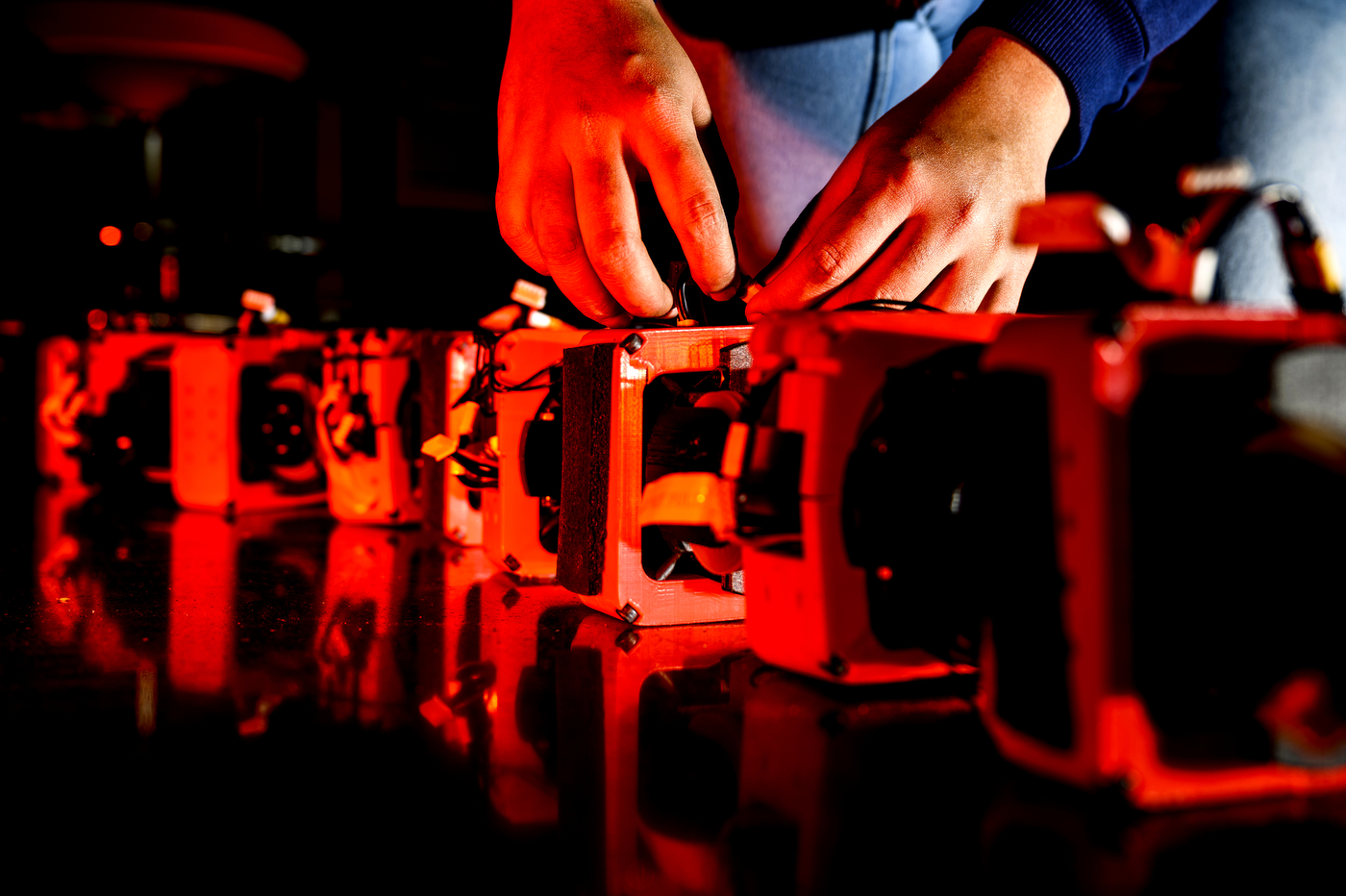

This article originally appeared on Northeastern Global News. It was published by Cesareo Contreras. Main photo: Northeastern Ph.D. student Adarsh Salagame works on a snake-like robot in the Experiential Institute of Robotics’ new lab space inside the EXP research complex. Photos by Matthew Modoono/Northeastern University

‘Experiential robotics’ on display at Northeastern. New space inside EXP features systems that span the technological gamut

The robots wield chopsticks, rotate platforms and look like snakes.

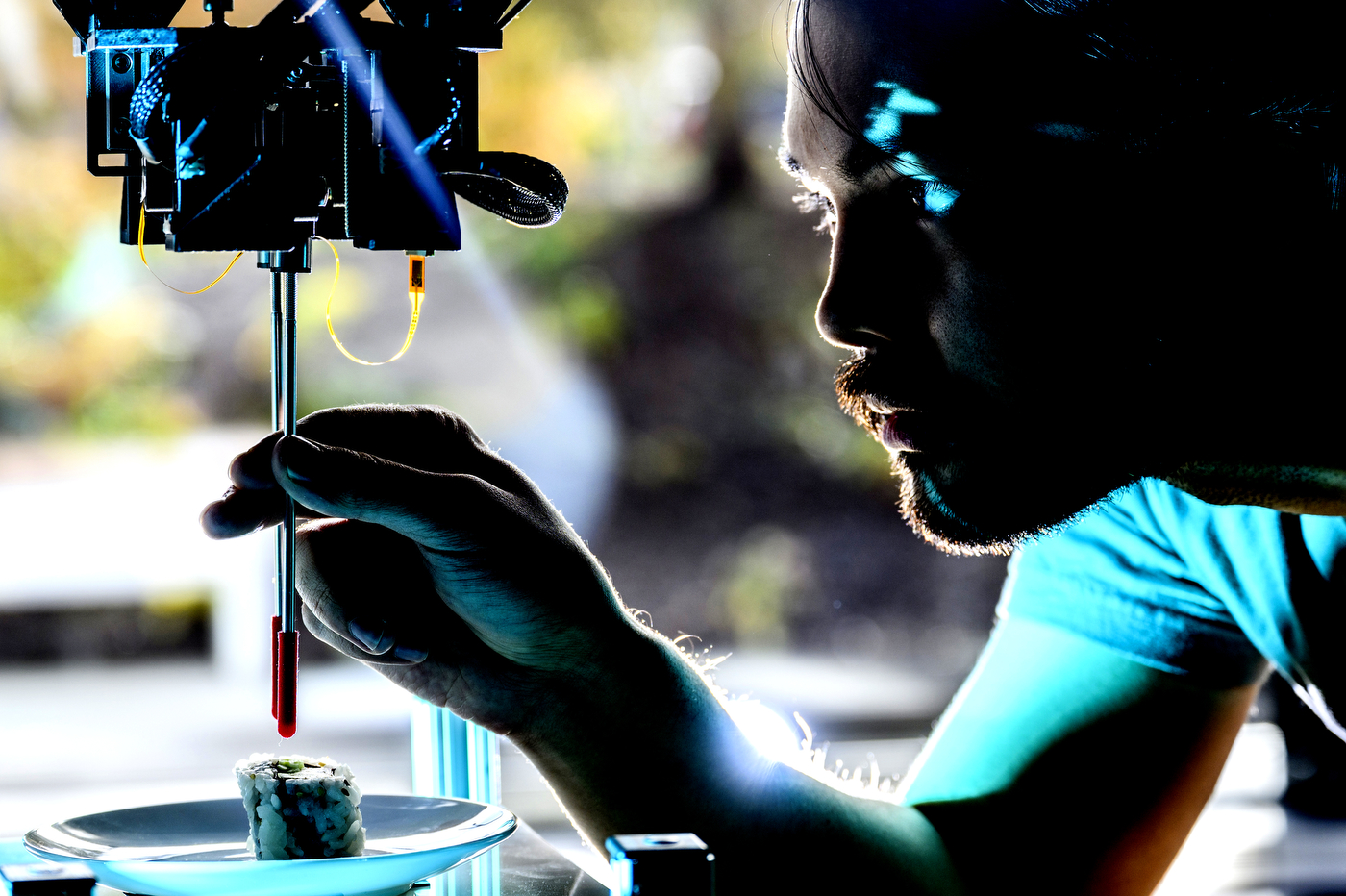

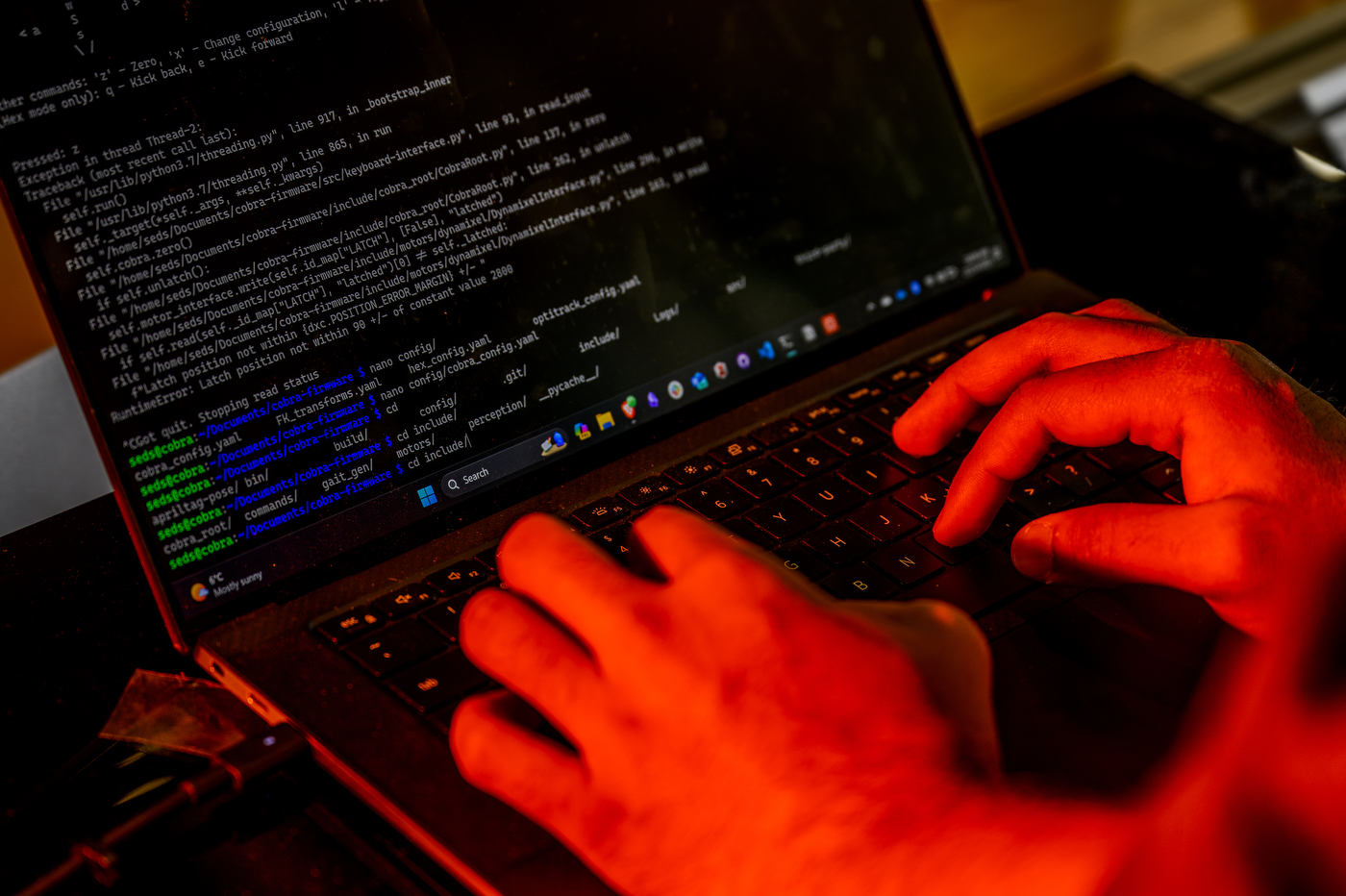

Roboticists at the Institute for Experiential Robotics’ lab in the new EXP building are conducting transformative research. Robots are handling chopsticks for precise hand manipulation. Research continues with a snake-like robot created for NASA’s BIG Idea Challenge that can navigate in sandy environments like the moon. And the lab has fabrication rooms for electronics, 3D printing and laser cutting.

|  |

|  |

Photos by Matthew Modoono/Northeastern University

The new space takes up the majority of the first level of the eight-story science and engineering complex on the Boston campus. Its high bay area is about the size of a basketball court — decked out with robotics systems spanning the technological gamut, including collaborative robots, industrial robot arms, mobile robots, drones, virtual reality systems and much more.

The institute also has space on the seventh floor of EXP that includes additional robots, and desk and lab space for researchers to conduct their work.

“Our mission is straightforward in my mind — enrich human experiences through meaningful development and deployment of robotics technology,” says Taskin Padir, Northeastern robotics professor and director of the institute.

“We’ve been working with the design team for the past six years even before the groundbreaking of the building,” he says. “We had a vision for the space where we can demonstrate what we mean by experiential robotics.”

Several Northeastern students and faculty in the lab are working on projects being led by Padir.

|  |

|  |

Photos by Matthew Modoono/Northeastern University

As part of a National Science Foundation grant, Northeastern developed a series of robotics applications designed to help workers in the seafood packaging industry use robots to move and pack products.

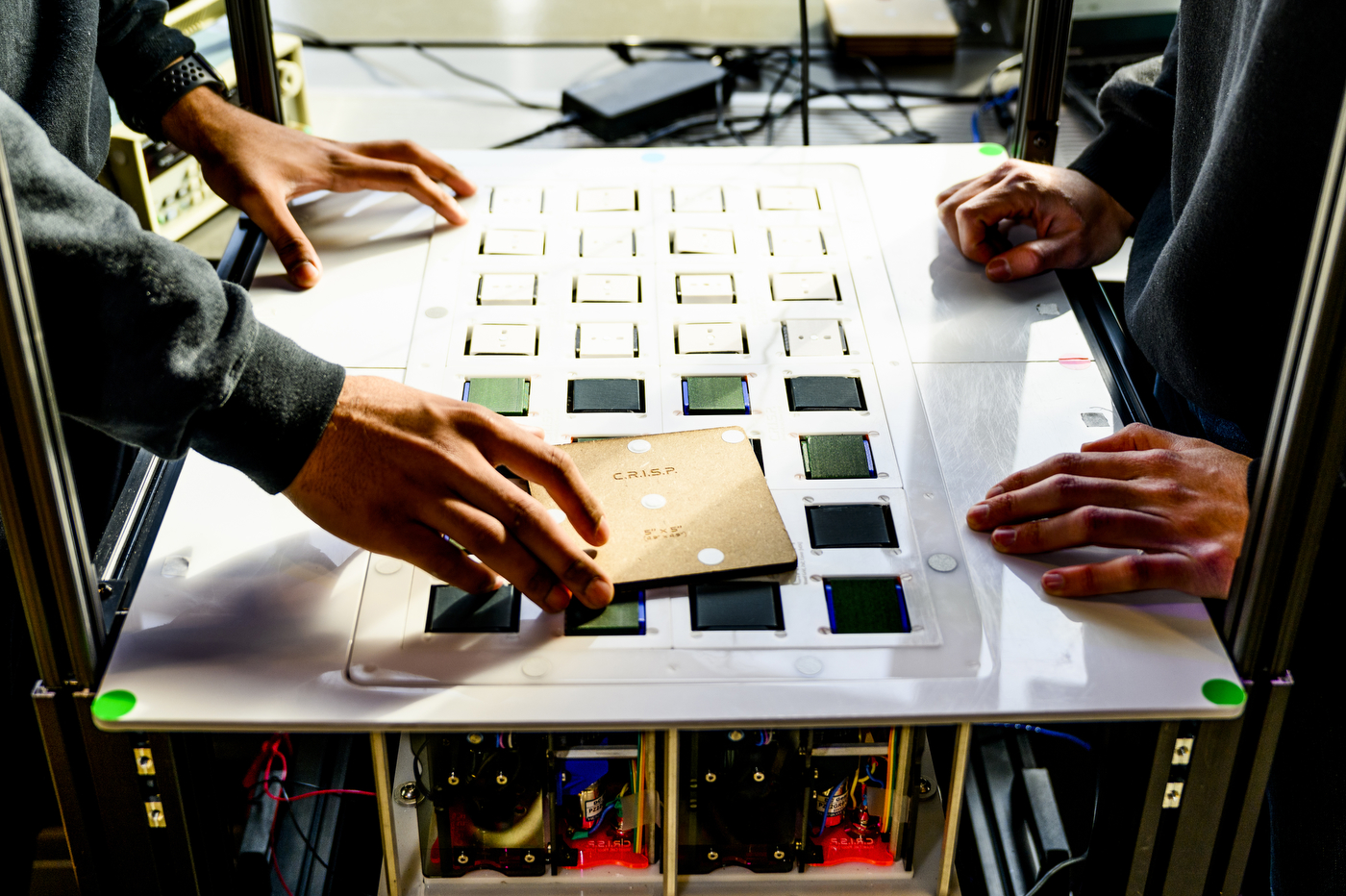

One of those systems involved creating a workstation that features an assistive robotic table. The name of the robotic system is VERA, which stands for voxel enabled robotic assistant.

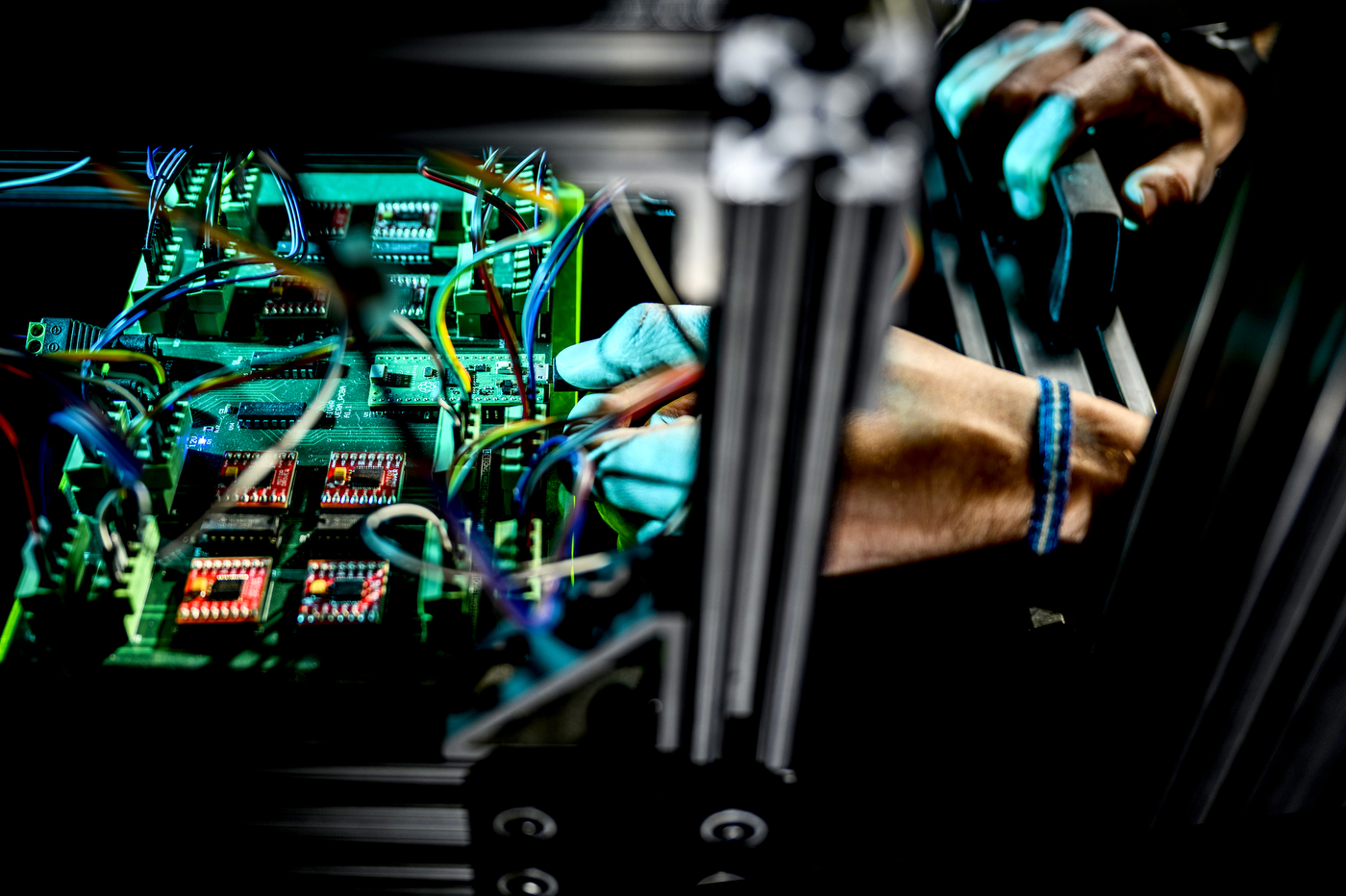

Embedded in the table is a series of robotic cube-like devices called voxels. The voxels are able to spin to help move the location of an object, such as plastic packaging. The workcell also features a mounted camera to track the movement of an object.

|  |

|  |

Photos by Matthew Modoono/Northeastern University

“The idea here was motivated by us having gone to seafood manufacturing sites and seeing people cut up really large fish like tuna and noticing that they had a lot of trouble moving around certain parts. So that motivated us to design a robot that wouldn’t interfere with your workspace,” says Mark Zolotas, a research scientist at Northeastern.

It’s a little different than what you would expect a typical robotic workcell to look since there are no robotic arms involved, he explains.

“We sort of see it as being a general way of rethinking about the way we view robots in general,” Zolotas says.

As of now, 20 faculty members working in a number of disciplines including robotics, artificial intelligence, computer science, physical therapy and entrepreneurship have a presence in the space, Padir says.

“It’s not the space or equipment that creates knowledge or pushes the boundaries of research,” Padir says. “It’s the people. Without researchers, we cannot do anything. It works in a hierarchical way — we have faculty who set the vision for projects then we have full-time postdoctoral researchers who help guide the Ph.D. students. We also have a very large cohort of master’s students in robotics. I envision they will get involved.”

Read full story at Northeastern Global News